2023-07-25

Publisher:AdministratorsSource:WebsiteViews:0

At present, the lithium battery industry has entered a stage of vigorous development under the combined effect of global energy shortage, scientific and technological progress and policy support. As the world's largest producer and consumer of lithium batteries, China is currently the world's largest energy storage and electric vehicle market. With the proposal of the goal of "carbon neutrality", lithium batteries have become the most important medium for new power systems and electric vehicle energy storage, providing strong support for reducing grid valley power waste and reducing carbon emissions.

In this context, Yuanhang Jinli has continuously optimized the product structure, upgraded and upgraded the product from the whole process of the industrial chain to the benchmarking industry "lighthouse factory" to inject new impetus into the sustainable development of the new energy industry.

"Lighthouse Factory" - committed to improving production efficiency and sustainable development to a higher level through innovation.

Previously, the world's leading power battery companies used AI, advanced analysis, edge/cloud computing and other technologies to achieve a defect rate of only 1/1 billion in three years when each group of batteries took 1.7 seconds to produce, while increasing labor productivity by 75% and reducing annual energy consumption by 10%. After this achievement, it became the first battery factory in the world to be rated as "Lighthouse Factory".

01. Improve factory digitalization

In order to actively respond to the call of China's "industrial power", further benchmark the leading enterprises and become a beacon factory of sustainable development, Yuanhang Jinli attaches great importance to the intellectualization of production lines. The factory production lines are fully popularized on the information platform. Key production data (such as downtime, production efficiency, defective rate, etc.) can be sent to the factory electronic screen through the system, and the information data is clear at a glance, The management can also view the real-time update of data through the client application, so as to achieve effective supervision. When the data is abnormal, the system can directly locate the responsibility alert to the person, greatly improving the timeliness of handling abnormal situations.

02. Control the quality of production line

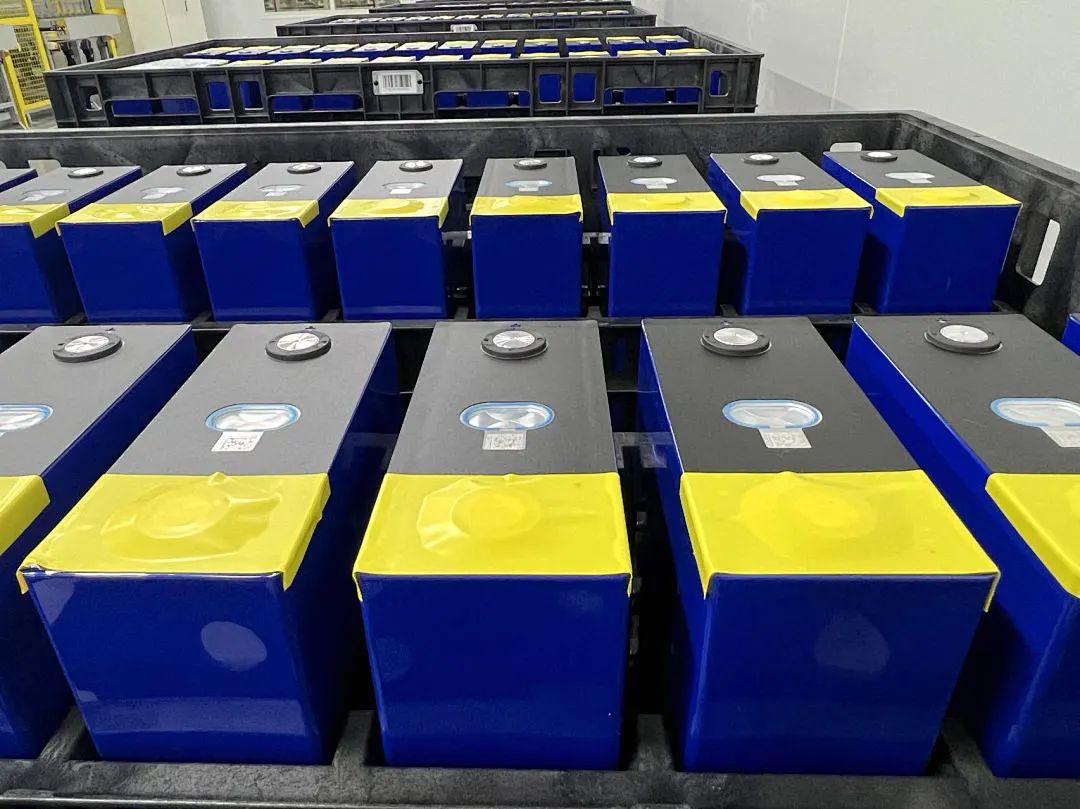

Quality is the lifeline of products. On the one hand, Yuanhang Jinli has applied the advanced quality inspection technology in the industry. With high-precision visual inspection equipment and AI technology, it has achieved three breakthroughs: high-precision defect detection of key welding stations, winding defect detection under complex working conditions, and defect detection of previous processes under high-speed fluid conditions.

On the other hand, Yuanhang Jinli always carries out the idea of "doing right once" for product quality, and all staff publicize that quality is produced, not tested. From the initial planning, the production and testing processes were integrated into one, the quality inspection was integrated into the production process, and a large number of intelligent devices were used to assist the detection. The number of quality inspectors was greatly reduced, and the quality was greatly improved. The personnel were only used to check the deficiencies.

03. Optimize benchmarking lighthouse factory

In a twinkling of an eye, Yuanhang Jinli Yancheng Base has been launched for one year. During the process of implementation, the plant equipment and facilities have been continuously improved, and the product production line has been continuously optimized and upgraded. 100% automation rate has been achieved in the coating workshop and welding and winding workshop, greatly reducing the degree of manual intervention. The quality determination is automatically scanned by online equipment, and the quality abnormality rate and labor cost have been effectively controlled.

It is not difficult to see that Yuanhang Jinli is striding towards benchmarking "lighthouse factory". At present, Yuanhang Jinli Yancheng Base has an annual production capacity of 5GWh and a daily output of about 20000 battery cells after full production. According to the current price of 0.65/Wh in the lithium iron phosphate energy storage battery cell market, it is preliminarily estimated that the annual sales can reach 3 billion yuan.

The emergence of the "lighthouse factory" has stimulated and helped most battery manufacturing enterprises. It is the industry leader in resetting standards. The whole industry is changing the past production and manufacturing thinking, thus improving the overall production and manufacturing level.

Next, Yuanhang Jinli will anchor its strategic goal of innovative development, benchmark against the "lighthouse factory", take digitization and intelligent low-carbon as the starting point, continuously strengthen the intelligent operation of the entire production process, activate high-quality development new momentum with efficiency and power changes, deepen the digital transformation of the entire industry chain system, scene innovation and application promotion, and make every effort to build Yuanhang Jinli into a world-class enterprise with more competitiveness and influence in the industry, To contribute to the transformation from "Made in China" to "Made in China".

Becoming a global energy storage and green power transportationCore technology leader

All rights reserved © Jiangsu Yuanhang Genlead New Energy & Technology Co.,Ltd

Copyright 2023 All Rights Reserved.

SuICPBei 2024075710-1

SuICPBei 2024075710-1